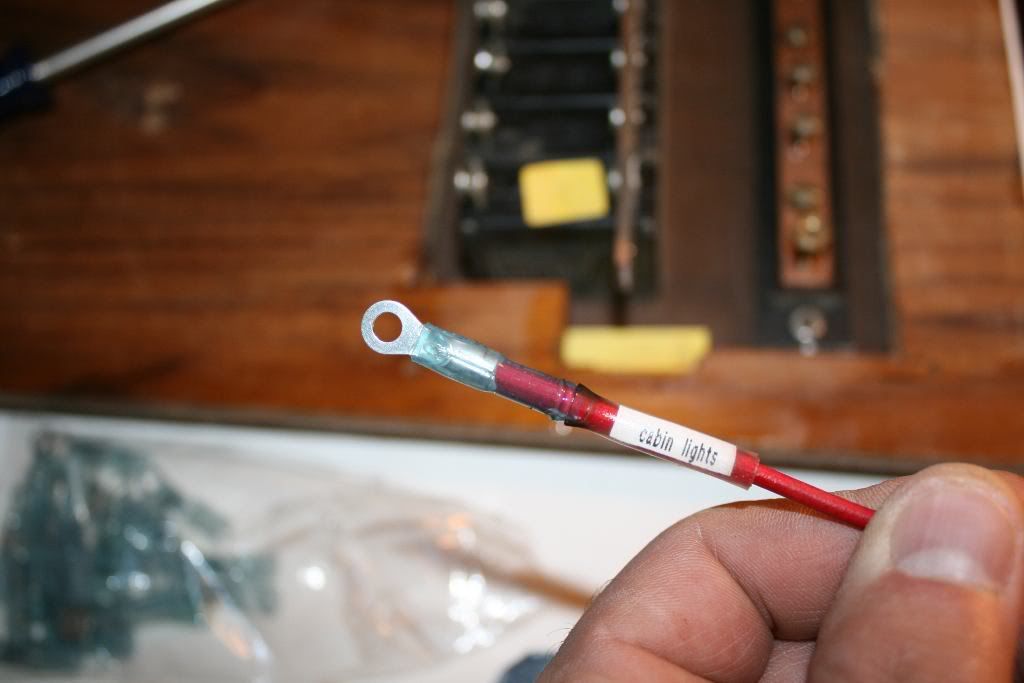

Well, quite a lot has been done the last few weeks, but it still feels like I'm not getting very far, I am about done with the electrical. The bilge

pump works, the fancy new LED nav

lights work, everything else electrical works, I even cranked the engine over yesterday (first time!) Of course the starting battery is toast, it sat for 2 years, I can charge it to 12.6v but a load test shows very little capacity, it worked good enough for me to test everything though, and since I have all the AC rewired and working, I can run the

battery charger and have

lights in the cabin! I also have a little $20 electric heater, it has two settings, 700w and 1500w, the 700w setting warms the cabin from say 30 degrees to a comfortable 55 in about 10 minutes. It is not that effective when it's 15 degrees out but luckily those days are past us this year. New house bank is on the float charger in my basement (two group 31's, Interstate MHD's I get them from work CHEAP) so now I still need a starting battery. And I need to rewire the mast.

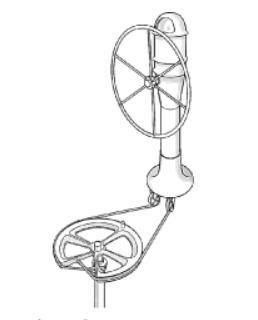

My plan was to start on the mechanical systems after the electrical was done, and yesterday I did just that. I fixed the steering! The steering works like this (experienced sailors can skip this part, this is for my family and friends) at the wheel there is a sprocket attached to a chain, the chain turns with the wheel, attached to both ends of the chain there is a cable, it rides on pulleys under the cockpit floor. Those pulleys change the direction of the cable from vertical to horozontal, the cables then go to a large idler attached to the rudder post.

The problem with my boat is the bolts that hold the ilders in their position (they are adjustable) fell off, so they were just flapping around and the cables fell off the pulleys. So I had to stick my head down the hatch and hang upside down while I put new nuts on the bolts, reroute the cable, climb out of that hatch and squeeze into the other one, attempt to route the cables on to the big idler, feel the cable fall off the pulleys (I can't see the pulleys from here) wiggle out, go into the other hatch, repeat until I get it right. Then I had to tighten the steering, then test it for binding (it did) loosen the bolts and get the pulleys to be in line with the cable, retighten, and check again. Now it works beautifully. All that sounded hard and time consuming, but it all took about an hour at the cost of a headache from hanging upside down for too long.

Next task is to fix the leaky fuel return lines. Of course they are braided, and they have compression fittings....That haven't been made in 30 years. So I asked the mechanic at the yard if they can make new ones, he said nope, but you can cut the flange off, there is a barb underneath that you can attach new lines to. I immediately understood what he's saying, it's like an air line or flexible brake lines (an air line you can fix that way, a brake line you cannot! So don't try it at home). Of course the fuel lines are tiny, 3/16" ID, and both sail supply stores don't have them, West Marine never heard of them despite the fact they are on their website, so I ordered those, that will be an easy fix.

I also installed a new bilge pump, a fully automatic kind but I bought it not knowing how it works, it runs every 2.5 minutes and checks for water, that will get super annoying real quick so I think I'll still use a float switch.

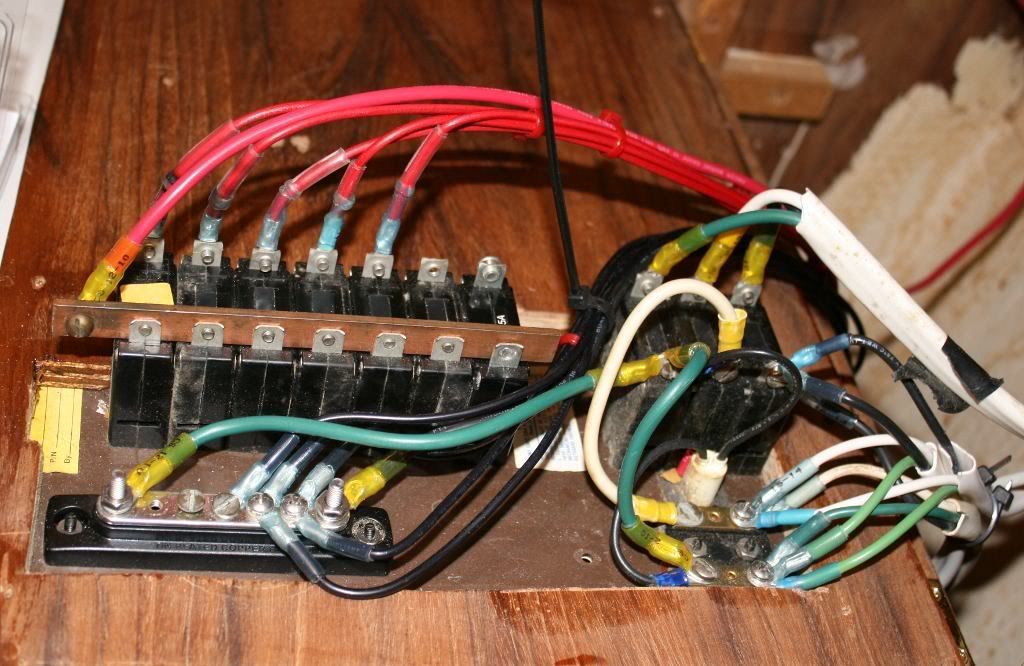

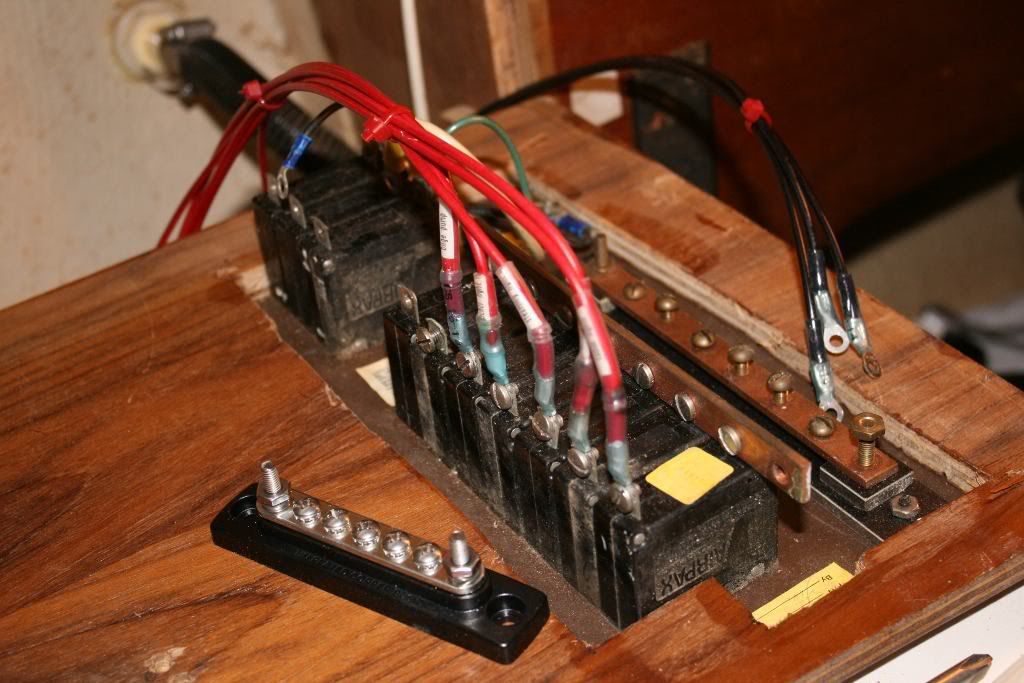

Almost finished wiring, the AC is different now, I added two short bussbars for neutral and ground. Next year I'm getting 2 separate panels, one for AC, one for DC. I don't like them both on the same panel.